From construction and manufacturing to aerospace and automotive industries, hydraulic systems are an essential part that provides precise control and powerful performance using pressurized fluid.

Understanding the principles of hydraulic system components and their associated benefits is crucial for anyone involved in the world of machinery, manufacturing, or heavy equipment.

In this article, we will delve into the fundamentals of hydraulic system components and the advantages they bring to various industries.

Components of The Hydraulic System

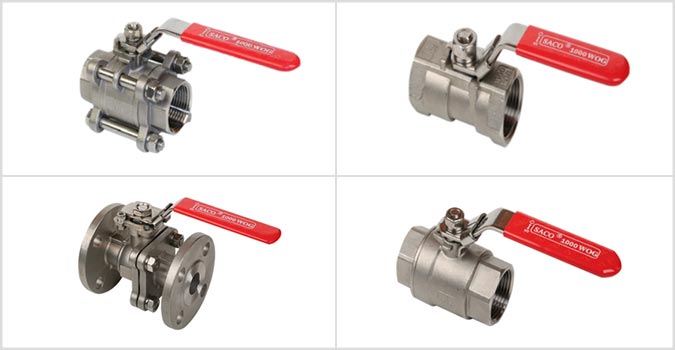

1- Hydraulic Valve

Hydraulic valve is one of the integral parts of a hydraulic system. It is a mechanical device designed to control and regulate the flow and direction of fluid.

They also play a vital role in ensuring precise control over the movement and pressure of the hydraulic actuators.

There are many various types of valves, such as directional control valves, pressure control valves, and flow control valves.

Hydraulic valves offer several benefits that contribute to the efficiency, control, and safety of the systems.

Benefits:-

- Efficiency

Hydraulic valves contribute to the overall energy efficiency of hydraulic systems by regulating fluid flow and pressure. With proper maintenance, hydraulic valves ensure the performance efficiency of hydraulic systems while minimizing energy consumption. - Precise Control

The precise control of hydraulic valves over the speed and direction of fluid flow is really essential for applications that require accurate and fine-tuned movements. - Safety

The hydraulic valves are equipped with safety features, such as pressure relief to prevent system damage in case of pressure spikes or malfunctions.

2- Hydraulic Pump

The hydraulic pump is used to force the fluid from the reservoir to the rest of the hydraulic system by converting mechanical energy into hydraulic energy.

As the heart of a hydraulic system, the basic concept of a hydraulic pump is to displace fluid volume against a resistive load or pressure.

Hydraulic pumps come in various shapes and sizes, including gear, vane, and piston. All different kinds of these pumps are designed for various uses.

Benefits:-

- Efficiency

In comparison to other pump types, like electric or pneumatic pumps, hydraulic pumps stand out as the most efficient component. They can produce greater pressures using less power and rely on minimal energy for their operation. - Precise Control

The design of the hydraulic pump enables enhanced control over the system’s motion and force, leading to precise outcomes in ideal applications. - Maintenance

Hydraulic pumps exhibit superior durability and demand minimal maintenance compared to other pump varieties. Crafted from high-quality materials, they can endure continuous operation with fewer components susceptible to wear or damage.

3- Hydraulic Hose and Fittings

Hydraulic hoses and fittings are also the top components in hydraulic systems because the operation of various hydraulic components relies on these two main parts.

A hydraulic hose is a flexible tube designed to transport hydraulic fluid from one part to another within a hydraulic system.

Concurrently, hydraulic fittings are used to connect and secure hydraulic hoses to other hydraulic components, such as pumps, valves, cylinders, or motors.

Altogether, these components ensure the proper circulation of fluid and make sure the hydraulic system functions as intended.

Benefits:-

- Maintenance

Maintaining hydraulic hoses and fittings is cost-effective and efficient, as they can be easily installed and replaced with minimal expenditure and time. - Efficiency

The hydraulic hoses and fittings are designed to minimize pressure loss and ensure the fluid flows efficiently. This enhanced fluid flow contributed to the improved performance of the hydraulic system. - Versatility

A variety of sizes and types of hydraulic hoses and fittings are available to accommodate diverse requirements in hydraulic systems. Additionally, they can be tailored to specific applications in order to meet the distinct needs of the system.

4- Hydraulic Actuators

Hydraulic actuators are integral elements within hydraulic systems that transform hydraulic energy, typically in the form of fluid pressure and flow, into corresponding mechanical energy.

They serve as pivotal components in a variety of industrial and mechanical scenarios, demanding both precision in control and the ability to handle substantial forces.

There are two primary types of hydraulic actuators: hydraulic cylinders and hydraulic motors.

Benefits:-

- Precise Control

Precise control over the motion and positioning of hydraulic actuators play a critical factor in ensuring the compatibility of the hydraulic system with the intended application. Therefore, it is essential to consider precision and fine-tuned adjustments when selecting the appropriate components for the system. - Reliability

Hydraulic actuators are known for their ability to endure challenging environmental conditions and heavy workloads without experiencing any breakdowns or significant wear and tear. In general, they have earned a reputation for their durability and reliability. - High Force and Torque

Due to their ability to generate significant force and torque, hydraulic actuators are ideally suited for applications that involve heavy lifting, pressing, or other tasks demanding high-force tasks.

5- Hydraulic Swivels and Rotary Joints

Hydraulic swivels and rotary joints facilitate the transfer of hydraulic fluid or other media from a fixed part of the hydraulic system to a component that rotates or pivots.

Hydraulic swivels are employed to safeguard against the twisting or damage of hydraulic hoses when rotation is involved.

While, the rotary joints are engineered to preserve the connection of hydraulic components while facilitating the transmission of fluids, gases, or other media within the system.

Both elements play a pivotal role in preserving a hydraulic connection while allowing for rotational or swiveling motion.

Benefits:-

- Maintenance

When appropriately maintained, hydraulic swivels and rotary joints facilitate precise control and operation, thus minimizing the necessity for frequent replacements and promoting extended service life. - Efficiency

In the pursuit of enhancing hydraulic system performance, these elements guarantee the efficient and steady conveyance of fluid or other substances between fixed and rotating components. - Versatility

Hydraulic swivels and rotary joints are recognized for their adaptability, as they can be customized to suit a wide range of applications across diverse industries.

Your Safe and Reliable Hydraulic Components Supplier in Malaysia

It’s essential to make sure that the hydraulic components align with the specific requirements of your application before making an investment in any components.

If you’re seeking guidance to locate a trustworthy hydraulic components supplier in Malaysia, Pusaco is here to assist you in selecting the most suitable products tailored to your requirements!

Also, don’t hesitate to contact our team for a FREE CONSULTATION if you have any uncertainties or require additional information about our products.

Have A Question?

Get in touch with us now!