In Malaysia’s evolving industrial automation sector, Festo pneumatic systems shine as symbols of innovation and reliability.

As a foremost producer of pneumatic components, Festo has significantly contributed to advancing automation technology across various industries in the country.

Their reputation as an ideal solution for technology is built on a strong foundation of cutting-edge products and commitment to exceeding customer needs.

The Power of Festo Pneumatics

Pneumatics involves compressing air or gases to power and control mechanical components, known as pneumatic systems.

These systems are widely used in machinery, engines, and industrial applications because they are quieter, less expensive to operate, and easier to use.

Festo takes pneumatic technology a step further by introducing elements that improve efficiency, and their actual cost-effectiveness is seen in their long-term benefits.

Key Components of A Pneumatic System

Festo is well-known for its unique pneumatic technology, offering a comprehensive range of pneumatic components tailored to diverse industrial needs.

They are committed in developing both high-performance and cost-effective solutions for industrial pneumatic systems.

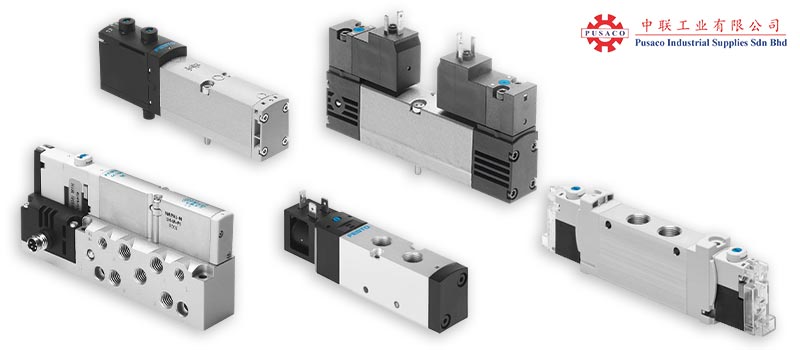

Valves

Valves are typically used to regulate the flow of compressed air in the system. Festo’s valve technology incorporates features like low power consumption and high flow rates.

Festo offers various types of valves, including solenoid valves, directional control valves, and pressure control valves. Solenoid valves use electricity for precise airflow control. Directional control valves guide the airflow, while pressure control valves regulate air pressure in specific system areas.

Air Preparation Units (FSU)

For pneumatic systems to operate well and last a long time, proper air preparation is essential. The filters, regulators, and lubricators found in Festo air preparation units are made to guarantee that compressed air is dry, clean, and operating at the proper pressure. This lowers downtime and maintenance costs while also improving the performance of pneumatic components.

Tubing and Fittings

Pneumatic systems rely on dependable tubing and fittings to function properly. Festo provides a wide range of tubing and fitting solutions that are wear-resistant and compatible with various compressed air systems.

Their push-in fittings, for example, provide rapid and secure couplings, making installation and maintenance simple. Festo also provides a wide range of tube materials and diameters to fulfill varying pressure and application needs.

Cylinders

Cylinders are the core of a pneumatic system, converting compressed air into linear motion. Festo provides various types, including single-acting and double-acting cylinders, round body cylinders, and compact cylinders.

Single-acting cylinders use air to extend the rod and a spring to retract it, while double-acting cylinders use air for both actions. Round body cylinders are the most common, and compact cylinders are ideal for tight spaces.

Delivering Cost-Effective and Reliable Festo Pneumatic Components in Malaysia

Optimizing efficiency while managing costs is crucial for any industry relying on pneumatic systems.

Pusaco, Malaysia’s leading industrial supplier, provides a range of cost-effective pneumatic components from Festo. Incorporating Festo’s pneumatic technology into your operations can enhance efficiency, reduce expenses, and maintain a competitive edge.

Whether it’s boosting productivity, ensuring reliability, or promoting sustainability, Pusaco invests in the future of efficient and cost-effective industrial solutions.

Interested in purchasing or need help finding the right components for better system operation? Our specialized team is ready to assist you. Feel free to reach out to us anytime.

Have A Question?

Get in touch with us now!