A Flow Aid System ordinarily denotes a system designed to improve and stimulate the movement of bulk materials in various industrial process.

EXEN Corporation is a prestigious Japanese company specializing in the design and development of vibration technology. They are also renowned for their innovative design of the EXEN Flow Aid System.

The implementation of vibrator technologies makes their Flow Aid System widely recognized as one of the simplest and most effective systems.

The Applications of EXEN Flow Aid System in Various Industries

EXEN Flow Aid System is effectively utilized in industries requiring efficient handling of materials such as powders, granules, or other bulk solids.

Factors Prompting The Utilization of EXEN Flow Aid System

The objective of the EXEN Flow Aid System is to prevent or alleviate issues that may disrupt materials flow, thereby leading to operational failures.

Here are four major issues that typically arise in hoppers, silos, or other storage vessels:-

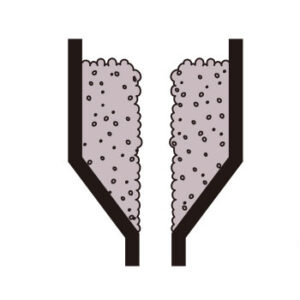

1- Bridging

Bridging occurs when material adheres to the outlet or opening of a hopper, silo, or container, impeding the unstricted flow of material and resulting in a blockage. This disruption can arise from factors such as the cohesive or adhesive properties, moisture, temperature, and the inherent characteristics of the material.

2- Ratholing

Ratholing occurs when material flows exclusively over the discharge opening, creating a column-shaped gap next to the hopper wall. This leaves the hopper filled with stagnant material that won’t be emptied.

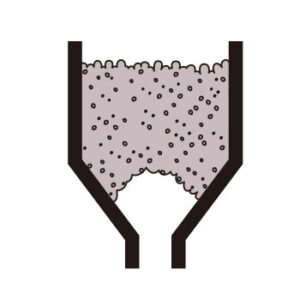

3- Arching

Arching occurs when material at the bottom of a hopper flows out through the discharge opening, forming a strong arch that can support the entire weight of the material in the hopper.

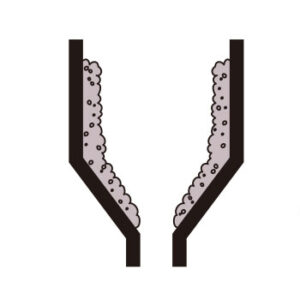

4- Adherence to Wall

Materials that are prone to sticking or affected by moisture/temperature tend to adhere to the hopper wall, impeding the flow.

Major Equipment Utilized in EXEN Flow Aid System

EXEN Air Knocker (Indirect Impact Type)

The Air Knocker (Indirect Impact Type) is a special tool that uses compressed air to make the piston forcefully hit the base surface, getting rid of powder sticking or clogging issues. It’s safe and cost-effective because it works only with air and can be used safely for powder that tends to stick during centrifugal vibration.

EXEN Air Knocker (Direct Impact Type)

The Air Knocker (Direct Impact Type) is a special equipment that uses compressed air to forcefully hit the hopper wall, effectively removing powder sticking or clogging. It’s safe and cost-effective, working only with air, and can be used safely for powder prone to sticking during centrifugal force. Unlike the indirect impact type that hits a fixed position, the air knocker is versatile, striking moving objects or targets with the knocker itself in motion. It’s used similarly to the indirect impact type.

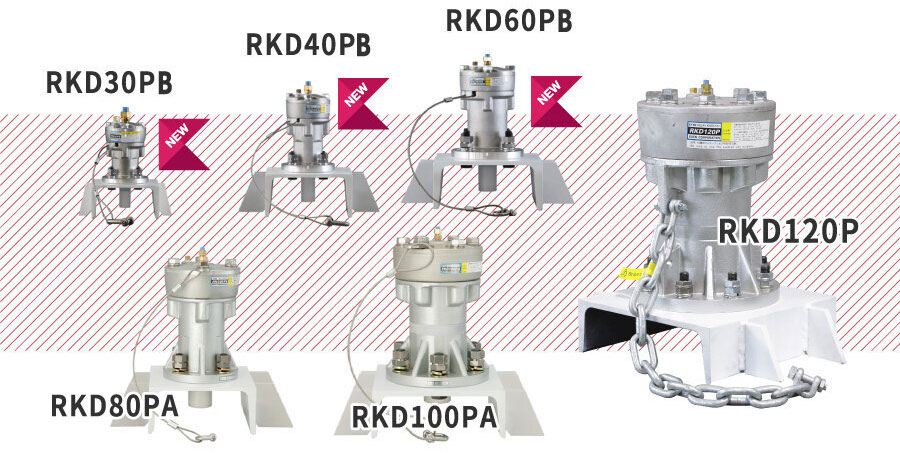

EXEN Pneumatic Blasters

A pneumatic blaster is a tool that utilizes compressed air to disintegrate blockages, guaranteeing a seamless flow of materials.

EXEN’s pneumatic blasters, including the Direct Blaster, Twin Blaster, Mini Blaster, and Micro Mini Blaster, are engineered to avert problems such as bridging or ratholing, ensuring improved efficiency in managing material flow challenges.

In addition to the mentioned devices, other equipment is utilized in the EXEN Flow Aid System. So, choose depending on the specific challenges in material flow and the needs of the industrial process.

Enhancing Your Industrial Processes with EXEN in Malaysia

It’s essential to know your specific type of Flow Aid System based on the characteristics of the bulk material, the storage vessel design, and the needs of your industrial processes.

Implementing these protocols is crucial for ensuring continuous production and avoiding downtime resulting from material flow challenges.

If you require support with equipment procurement or guidance, rely on Pusaco, a reputable industrial supplier, to assist you in selecting the appropriate products.

Contact our team for a COMPLIMENTARY CONSULTATION, and we will aid in enhancing your industrial processes.